DFT TELECOM

Stainless Steel Spiral Tube Armored DTS Distributed Temperature Sensor Fiber Cable

Stainless Steel Spiral Tube Armored DTS Distributed Temperature Sensor Fiber Cable

픽업 사용 가능 여부를 로드할 수 없습니다.

Main Cable Parameter

|

Size(mm) |

Tensile(N) |

Crush Resistance(N/100mm) |

Bending Radius(mm) |

Cable loss(db/km) |

||||

| Ф3.0 |

Long Term |

Short Term |

Long Term |

Short Term |

Dynamic |

Static |

MM |

|

| 200 | 400 | 2000 | 3000 | 20D | 10D | 850nm | 1300nm | |

| ≦3.5 | ≦1.0\5 | |||||||

Temperature -20℃-70℃ -4℉-158℉

The fiber optic cable must be designed and manufactured with adequate protection of the distributed sensing fibre in the specific environment. Additionally, the cable must be designed to ensure that the Distributed Temperature Sensing (DTS) cable has the optimum thermal conductivity. we has vast experience in designing and manufacturing cables that achieve the balance between sensitivity and protection for a range of different industrial sensing applications. This varies from the extremely rugged components used in oil wells to lightweight flexible cables designed for the dam industry that are easy to handle but can survive large compaction forces. Depending on the specific installation and environment these cables can have lifetimes of 30 years plus.

Sensor cable installation components

In order to maintain the integrity of the optical path of the Distributed Temperature Sensor along the entire length of the installation, it is necessary to engineer and manufacture components at critical points along the sensing cable path. This can vary from simple junction boxes used in controlled environments, to specialised splice joints used in downhole environments through to high pressure chambers’ that are certified for use in zone 0 hazardous areas (eg wellhead outlet). sensor fiber cable has a wide range of components for use in industrial applications. This can either be standard items or will be designed according to the customer’s specific requirements.

Sensors designed for extreme environments

We have qualified a range of specialised distributed temperature sensing cables. These can withstand temperatures across a wide varieties of temperature that vary from cryogenic applications (eg LNG leak detection) up to high temperature process applications in excess of 300 °C. In addition Sensornet has developed sensing cables that can survive in hostile, high pressure, hydrogen rich atmospheres.

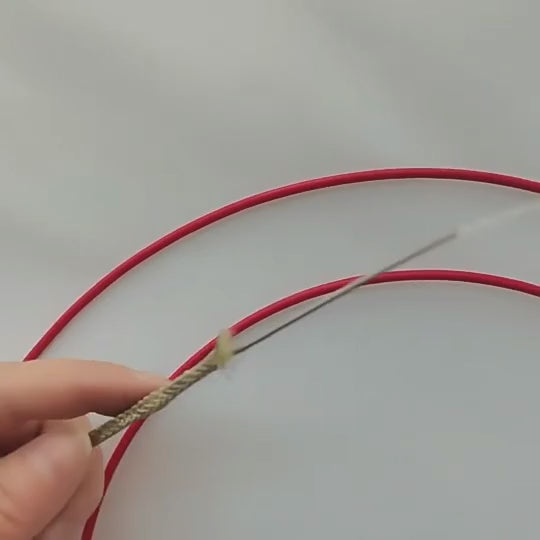

2, Structure of sensing fiber optic cable

|

Cable structure |

Material /model |

Specifications |

|||||

| 1 | Optical Fiber | 62.5/125 | Ф0.6±0.05 | ||||

| 2 | Metal Tube | Stainless steel | O.D | Ф1.5±0.1 | |||

| I.D | Ф1.1±0.1 | ||||||

| Thickness | 0.2±0.02 | ||||||

| Clearance | 0.20±0.05 | ||||||

| 3 | Tensile | Kevlar | 1100DTEX | ||||

| 4 | Metal Braiding | Stainless steel | Ф0.07*6*16(36*24*27*27) | ||||

| 5 | Jacket | LSZH | O.D | Ф3.0±0.1 | |||

| Thickness | ≥0.4 | ||||||

Application

Monitoring Cryogenic applications in LNG Plants

Oil & Gas Pipeline leak detection

High voltage power cable monitoring

Dam seepage and environmental DTS monitoring

Packing delivery

Delivery: 3-7 working days, depends on quantity.

Packing: wooden reel,carton box or as required